The Role of China Rapid Prototype Suppliers in Modern Business

In an era where innovation and speed are critical, China rapid prototype suppliers have emerged as pivotal partners for businesses looking to enhance their production processes and deliver products that meet ever-evolving market demands. This article delves deep into the arena of rapid prototyping, particularly focusing on the invaluable contributions and advantages these suppliers offer, especially in the realm of metal fabrication.

What is Rapid Prototyping?

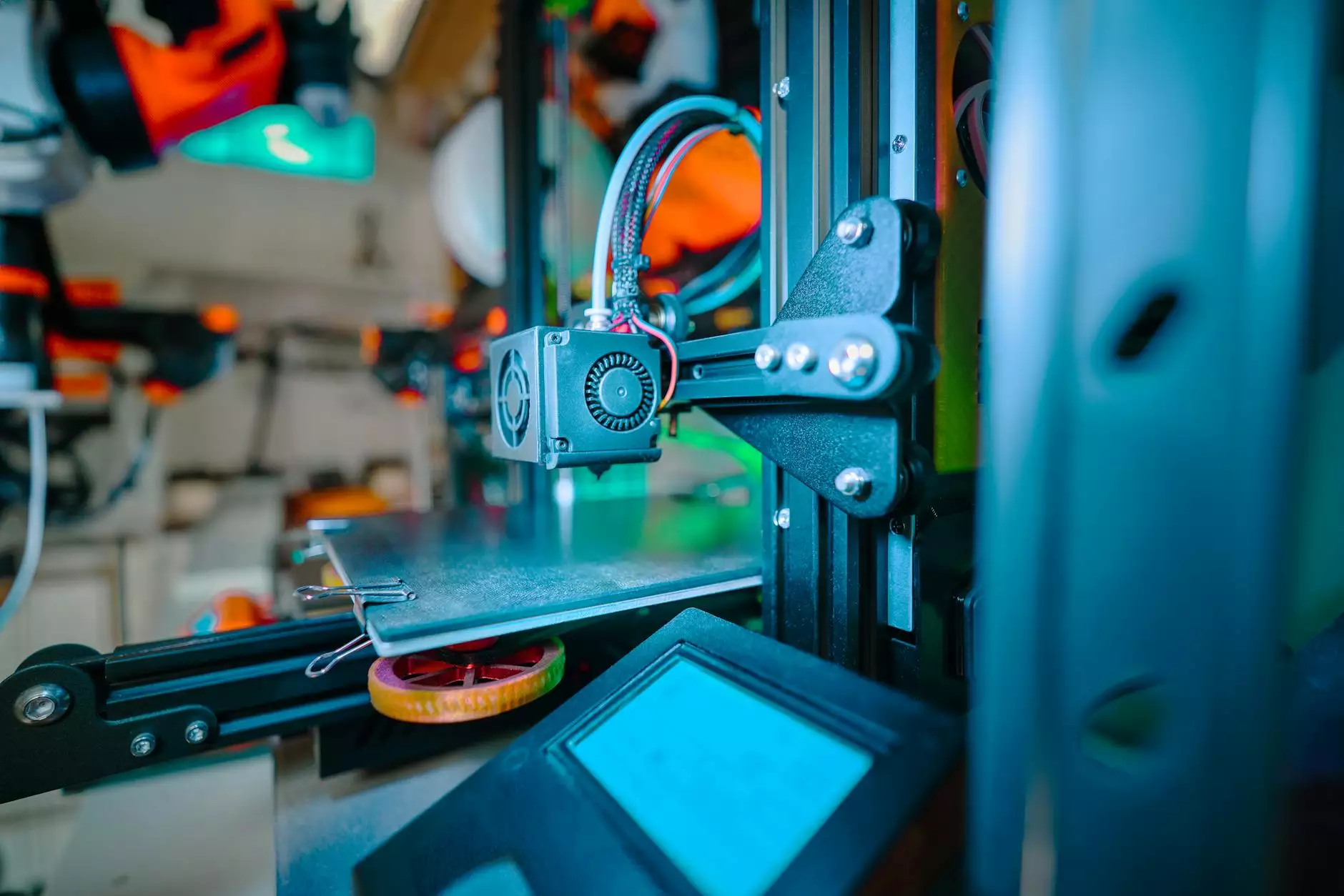

Rapid prototyping is an advanced manufacturing technique that enables the quick fabrication of a scale model or prototype of a physical part or assembly using three-dimensional computer-aided design (CAD) data. The aim is to transform ideas into tangible products in the shortest time possible. This revolutionizes product development cycles, reducing lead times from months to just a few days.

Why Choose China for Rapid Prototyping?

China has established itself as a global powerhouse in manufacturing and rapid prototyping. Here are some compelling reasons why businesses worldwide are increasingly turning to China rapid prototype suppliers:

- Cost Efficiency: Chinese suppliers offer competitive pricing due to lower labor costs and a robust supply chain.

- Advanced Technology: Many Chinese factories are equipped with the latest in 3D printing and CNC machining technologies.

- Scalability: These suppliers can scale your prototype production up or down based on demand, ensuring flexibility in order fulfillment.

- Speed: The integration of cutting-edge technologies enables faster turnaround times, which is crucial in today’s fast-paced market.

- Expertise: China's extensive experience with foreign clients allows suppliers to understand and meet global standards seamlessly.

Key Benefits of Working with China Rapid Prototype Suppliers

Engaging with China rapid prototype suppliers results in a multitude of benefits that can significantly impact business operations and product outcomes:

1. Accelerated Time to Market

In the competitive landscape of modern business, time is of the essence. With rapid prototyping, suppliers in China can help you create and test prototypes quickly, thereby reducing the overall product development cycle. This accelerated pace allows companies to get their products into the hands of consumers faster, which can be a significant competitive advantage.

2. Enhanced Collaboration

China suppliers often emphasize their collaboration capabilities. By developing a close partnership, businesses can benefit from shared insights and expertise that lead to better products and solutions. This collaboration fosters innovation, as your ideas and feedback help shape the prototype's design and functionality.

3. Diverse Material Options

Chinese suppliers offer a wide range of materials for rapid prototyping, from plastics to metals. This diversity allows businesses to choose the best materials that meet their functional and aesthetic needs. Whether you require durable metals for industrial applications or lightweight materials for consumer products, you can find suitable options.

4. High Precision and Quality

Quality control is paramount in prototyping. Most Chinese suppliers adhere to international standards and use advanced technologies to ensure high precision in their prototypes. This commitment to quality translates into reliable and functional prototypes that can withstand real-world conditions.

How to Select the Right China Rapid Prototype Supplier

Choosing the right China rapid prototype supplier is crucial for your project's success. Consider the following factors when making your choice:

- Reputation: Research potential suppliers' reputations by checking reviews, testimonials, and case studies.

- Technical Capabilities: Assess whether the supplier possesses the technology and skills necessary for your specific prototyping needs.

- Communication: Effective communication is vital. Choose a supplier who is responsive and provides clear information throughout the process.

- Lead Times: Ensure the supplier can meet your deadlines without compromising quality.

- Post-Production Support: Consider the level of support offered after prototype delivery, including adjustments and refinements.

The Processes Involved in Rapid Prototyping

The workflow within China rapid prototype suppliers generally follows a well-defined process. Here’s an overview:

1. Initial Design and CAD Modeling

The first step involves the creation of a digital model using CAD software. This model serves as the blueprint for the prototype. It's critical for the accuracy and reliability of the final product.

2. Prototype Development

Once the CAD model is ready, the supplier uses various methods such as 3D printing, CNC machining, or injection molding to create the physical prototype. The choice of method depends on the materials used and the prototype’s complexity.

3. Testing and Iteration

After prototype creation, rigorous testing is conducted to evaluate its functionality, durability, and overall design. Any necessary adjustments are made based on feedback from stakeholders.

4. Finalization and Production

Once the prototype meets all requirements and passes testing, it can be finalized for mass production. Suppliers can seamlessly transition from prototyping to full-scale manufacturing, leveraging the same technologies used in prototyping.

Challenges Faced by China Rapid Prototype Suppliers

While there are numerous advantages, certain challenges can arise when working with China rapid prototype suppliers:

- Language Barriers: Miscommunication can lead to errors, emphasizing the need for clear and concise communication.

- Quality Consistency: Ensuring consistent quality across multiple production runs can be challenging. It’s essential to choose suppliers that prioritize quality control.

- Intellectual Property Concerns: Protecting your designs and ideas is crucial. Businesses must ensure that their intellectual property is secured when working with overseas suppliers.

Future Trends in Rapid Prototyping

The landscape of rapid prototyping is constantly evolving. As technology advances, we can expect several emerging trends that could reshape the market:

1. Increased Use of AI and Machine Learning

Artificial intelligence will play a significant role in streamlining prototyping processes, optimizing designs, and improving decision-making in manufacturing.

2. Sustainability Initiatives

With growing awareness of environmental issues, suppliers will increasingly focus on sustainable practices, including the use of eco-friendly materials and waste reduction techniques.

3. More Advanced Material Technologies

The development of new materials, such as biodegradable plastics and lightweight composites, will provide even greater flexibility and functionality in prototyping.

Conclusion

In summary, China rapid prototype suppliers have become an indispensable resource for businesses aiming to innovate and deliver high-quality products efficiently. By leveraging their capabilities, companies can accelerate their time to market, enhance collaboration, and improve product quality. However, it is essential to conduct thorough research and choose the right partner to navigate the challenges and unlock the full potential of rapid prototyping. As trends continue to evolve, embracing these changes will enable businesses to stay ahead in an increasingly competitive landscape.

For more information and to explore quality metal fabrication, visit DeepMould and discover how we can help you innovate and succeed.