Unveiling Excellence in Manufacturing: The Power of Metal Fabricators and Injection Molded Plastic Manufacturers

In today’s rapidly evolving industrial landscape, the demand for high-quality, efficient, and innovative manufacturing solutions has never been greater. Companies worldwide are seeking reliable partners that can transform ideas into tangible, durable products through cutting-edge technology and expert craftsmanship. This article explores the vital roles of metal fabricators and injection molded plastic manufacturers, highlighting their significance, processes, and how they are shaping the future of manufacturing at leading establishments like DeepMould.net.

Understanding the Foundation: The Role of Metal Fabricators in Modern Industry

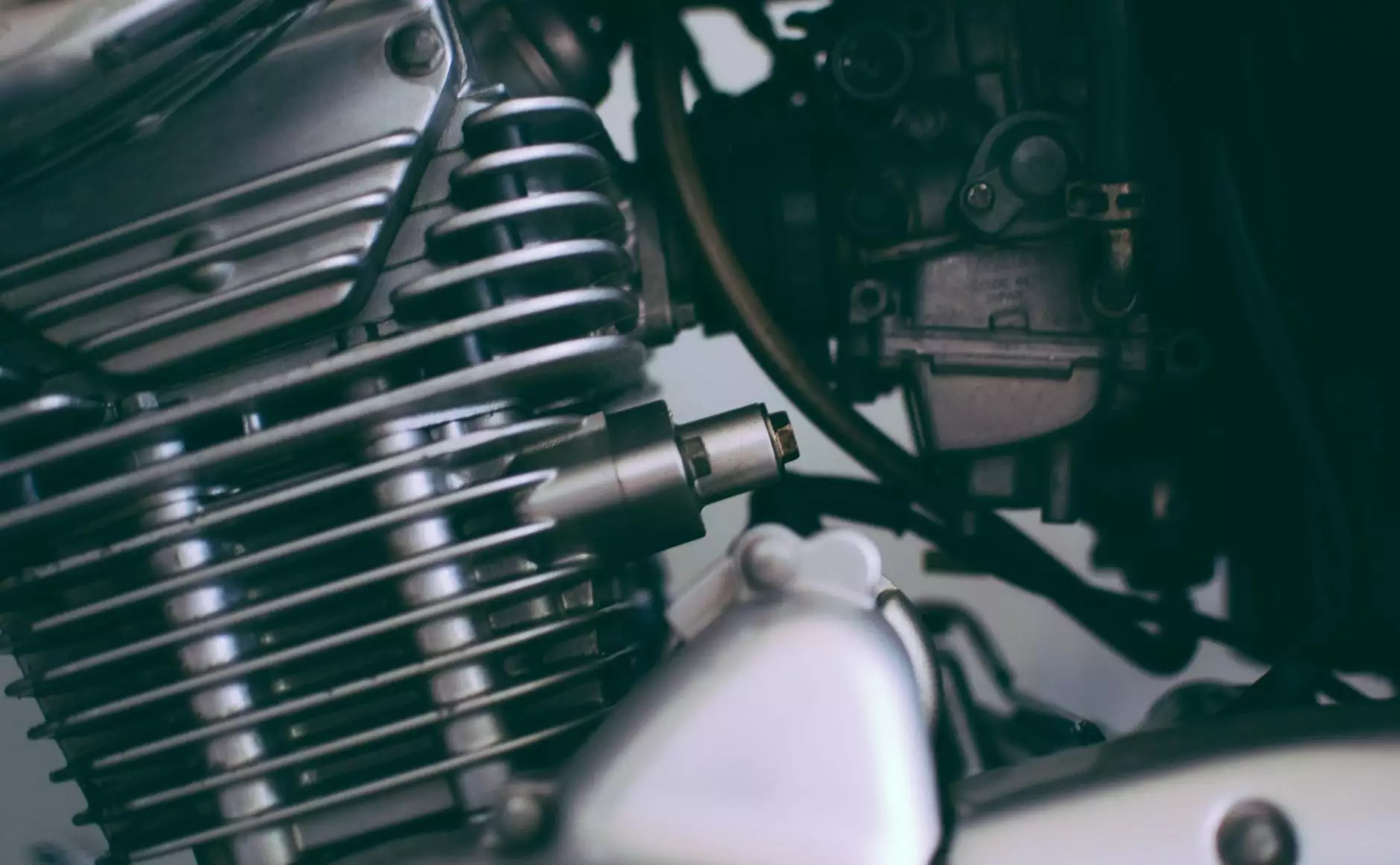

Metal fabrication is an age-old craft that has evolved into a sophisticated, high-precision process pivotal to countless industries, from aerospace and automotive to construction and consumer electronics. Metal fabricators are skilled professionals who transform raw metal sheets, bars, or other forms into complex components and structures through an array of manufacturing techniques.

What Do Metal Fabricators Do?

- Cutting and shearing: Precise trimming of metal sheets and profiles to specified dimensions.

- Bending and forming: Shaping metals into desirable contours using presses and rollers.

- Welding and assembling: Joining metal parts with techniques like TIG, MIG, or arc welding to create larger assemblies.

- Finishing processes: Surface treatments such as grinding, polishing, or coating for durability and aesthetics.

Innovation in Metal Fabrication

Modern metal fabricators leverage advanced CNC machinery, robotic automation, and quality control systems to deliver unrivaled precision and efficiency. These innovations enable the production of complex geometries and high-strength components essential for demanding applications.

The Rise of Injection Molded Plastic Manufacturers in Manufacturing Ecosystems

While metal fabrication is essential, the demand for lightweight, cost-effective, and versatile plastic components has surged, positioning injection molded plastic manufacturers at the forefront of modern production lines. Injection molding is a highly efficient process for mass-producing intricate plastic parts with tight tolerances.

Core Processes of Injection Molding

- Design and mold creation: Engineering custom molds suited for the specifications of the part.

- Material selection: Choosing suitable thermoplastics or thermosets based on strength, flexibility, and environmental resistance.

- Injection process: Melting plastic pellets and injecting them under high pressure into the mold cavity.

- Cooling and ejection: Allowing the plastic to solidify before ejecting the finished component.

- Post-processing: Trimming excess material, finishing surfaces, or assembling multiple parts.

The Advantages of Injection Molding

- High volume production: Capable of producing thousands to millions of identical parts efficiently.

- Design flexibility: Enabling complex geometries, integrated features, and intricate details.

- Cost-effectiveness: Lower per-unit costs at high volumes due to automation and rapid cycle times.

- Material versatility: Wide range of plastics offering various physical and chemical properties.

Synergies Between Metal Fabricators and Injection Molded Plastic Manufacturers

The integration of both metal and plastic manufacturing processes yields unparalleled advantages, such as:

- Enhanced product performance: Combining metal’s strength with plastic’s lightweight nature for optimized, resilient products.

- Cost optimization: Using metal for structural components and plastics for intricate or cosmetic parts reduces overall manufacturing costs.

- Accelerated development cycles: Rapid prototyping and flexible tooling enable faster time-to-market.

- Customization and innovation: Achieving tailored solutions through hybrid assembly or multi-material components.

Why Choose DeepMould.net for Your Manufacturing Needs?

DeepMould.net stands out as a premier destination for companies seeking expert metal fabricators and injection molded plastic manufacturers. Our commitment to excellence and innovation ensures that clients receive products crafted to the highest standards, supporting their strategic goals in various sectors.

Key Features of DeepMould.net's Manufacturing Services

- Advanced technology: Utilizing state-of-the-art CNC machines, robotic welding, and high-precision injection molding tools.

- Customized solutions: Tailoring manufacturing processes, materials, and designs to meet specific client requirements.

- Quality assurance: Implementing rigorous quality control protocols at every stage of production.

- Environmental responsibility: Emphasizing sustainable practices, material recycling, and eco-friendly production methods.

- Global expertise: Serving international clients with comprehensive engineering, prototyping, and mass production capabilities.

Choosing the Right Manufacturing Partner in Today's Business Climate

In the competitive environment of manufacturing, selecting a partner like DeepMould.net offers several advantages:

- Technical mastery: Combining expertise in metal fabrication and plastic injection molding ensures versatile product development.

- Cost efficiency: Streamlined processes and high throughput reduce overall production costs.

- Reliability and consistency: Dependable supply chains and quality controls produce uniform, high-quality products.

- Innovation support: Collaborating on design improvements, material selection, and manufacturing techniques for cutting-edge solutions.

The Future of Manufacturing: Trends to Watch

The industry is continuously transforming, with emerging trends shaping how metal fabricators and injection molded plastic manufacturers operate:

- Automation and smart manufacturing: Integrating AI, IoT, and robotics for enhanced precision and productivity.

- Sustainable materials and practices: Growing emphasis on eco-friendly plastics, recyclable metals, and green processes.

- Rapid prototyping and additive manufacturing: Combining traditional fabrication with 3D printing for faster development cycles.

- Customized manufacturing: Emphasizing flexible, small-batch production to meet bespoke client needs.

Conclusion: Building a Future of Manufacturing Excellence

Whether it is through sophisticated metal fabrication techniques or innovative injection molded plastic manufacturing, the key to successful product development lies in partnering with a provider who prioritizes quality, technological advancement, and client satisfaction. Companies like DeepMould.net exemplify the perfect blend of expertise, innovation, and dedication necessary to thrive in today's challenging market.

As industries evolve, the collaboration between metal fabricators and injection molded plastic manufacturers will become even more critical, delivering versatile, durable, and cost-effective solutions that meet the highest standards of excellence. Investing in such partnerships ensures a competitive edge, rapid innovation cycles, and sustainable growth in your manufacturing endeavors.

Discover the Difference with DeepMould.net Today

Explore the comprehensive manufacturing solutions of DeepMould.net — your trusted partner in transforming ideas into impactful products. From initial design to mass production, our team is committed to delivering unparalleled quality and service, empowering your business to reach new heights of success.